- Products

- Striim Cloud

- Striim Platform

- Striim for BigQuery

- Striim for Databricks

- Striim and Microsoft Fabric

- Striim for Snowflake

Cloud SecurityLearn how Striim Cloud uses best-in-class security features for networking, encryption, and secret storage.

Whats New in Striim 5.0Discover transformational decision-making by integrating real-time data and real-time AI to accelerate business performance and growth.

- Solutions

- Striim Solutions for AI and ML

- Streaming Integration

- High Availability

- Striim on AWS

- Striim Cloud

- Striim and Microsoft Azure

- Financial Services

- Retail and CPG

- Striim Solutions for Healthcare and Pharmaceuticals

- Striim Solutions for Hospital Systems

- Striim Solutions for Travel, Transportation, and Logistics

- Striim Aviation

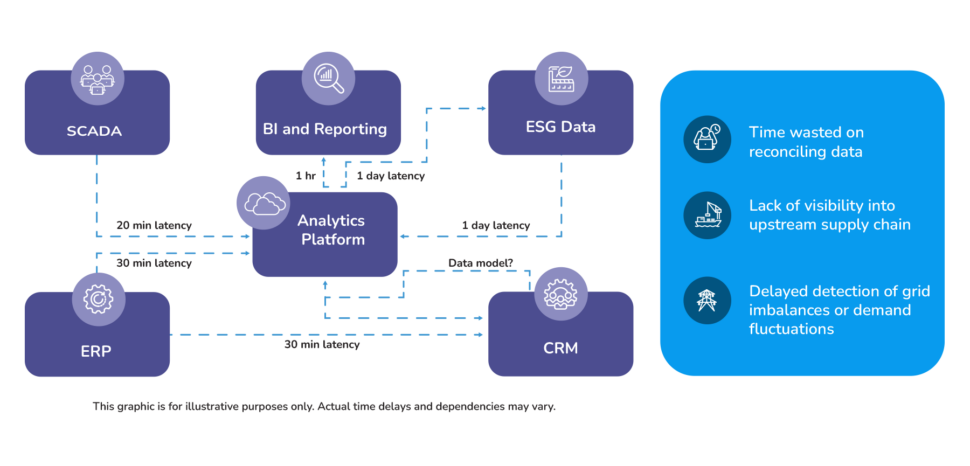

- Striim Solutions for Manufacturing and Energy

- Striim Solutions for Telecommunications

- Striim Solution for Technology

- Striim Media

TECHNOLOGIES - Pricing

- Customers

- Connectors

- Resources

- Company

- Free Trial